1000 series aluminum is regarded as commercially pure aluminum, and it has 99%-99.9% of aluminum with no major alloying additions. These compositions have features of small density, high electrical and thermal conductivity, excellent corrosion resistance and low mechanical properties. These alloys are non-treatable, and are well suited for applications involving severe forming because they harden more slowly during the forming process. In addition, this series alloy takes extremely well to welding and is the most weldable of all aluminum alloys, allowing gas welding, atomic welding and contact welding, and not easy for braze welding. These alloys also feature excellent workability, ease of press working, extending and bending.

1000 series aluminum alloys (with minimum of 99.9% aluminum) can be widely used for scientific experiment, chemical industry and special applications.

1070 aluminum alloy is widely used for busbars, heat-exchangers, metallizing, electrical material, building and construction, transport, high-end oxidizing material, electronic aluminum foil, PS plates, strips for ornaments, communication cables, for joining two pieces of aluminum.

Read More

1100 aluminum alloy is commonly used for HVAC, heat shield, deep drawn applications, cosmetic bottle cap, heat exchanger fins, spun hollowware, dials and name plates, decorative parts, giftware, cooking utensils, rivets and reflectors, and sheet metal work.

Read More

1050 aluminum alloy is used for the manufacture of heat sinks, chemical process plant equipment, food industry containers, pyrotechnic powder, lamp reflectors, cable sheathing, automotive industry, architectural and paneling, general sheet metal work, cabinets, vessels and appliances, PS CTP printing plate.

Read More

1060 aluminum alloy is widely used in the manufacture of railroad tank cars, chemical equipment, ship equipment, conductive material, welding rod, gauge and instrument.

Read More

1145 aluminum alloy is applied in packaging, thermal insulation aluminum foil, heat exchangers.

Read More

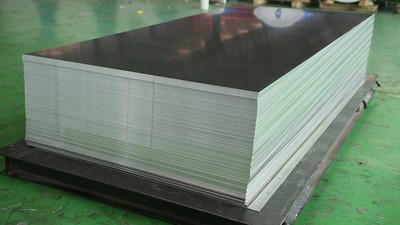

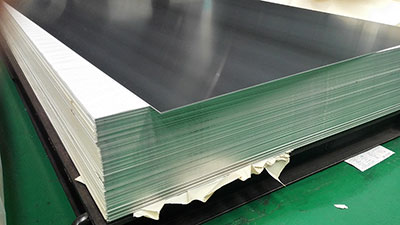

To pack the aluminum sheet/plate/coil, first of all, put a layer of plastic film with a thickness of no less than 0.08mm in the packing box, then a layer of EPE foam, the third layer of PE kraft paper, and finally put the desiccant.